PK-3 Electrode Polishing kit (cat#013223)

|

|

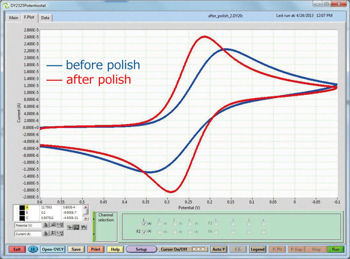

| With repeated electrochemical redox reaction experiments, the adhesion of the experimental products on to the electrode surface, and the electron transfer rate is attenuated gradually. If the electron transfer speed becomes slow, the difference between peak potentials for oxidation and reduction will broaden. | Refreshing the electrode surface by polishing, the electron transfer rate will increase again. Consequently, the peak potential difference becomes narrow and returns to an ideal CV. Electrode: Glassy carbon electrode |

Description

| Catalogue No. | Description |

| 013223 | PK-3 Electrode Polishing kit |

| Contents | |

| 012620 | 0.05 µm polishing alumina (20 mL) |

| 012621 | 1 µm polishing diamond (10 mL) |

| - | Alumina polishing pad (10 pcs) |

| - | Diamond polishing pad (10 pcs) |

| 013222 | Replacement glass plate for PK-3 (1 pc) |

| Polishing pad for acquisition separately | |

| 012600 | Alumina polishing pad (20 pcs) |

| 012601 | Diamond polishing pad (20 pcs) |

Option(sold separately)

| Catalogue No. | Description | Quantity | purpose |

| 012620 | 0.05 µm polishing alumina (20 mL) | 1 | For final polishing |

| 012621 | 1 µm polishing diamond (10 mL) | 1 | For intermediate polishing |

| 013234 | 6 µm polishing diamond (10mL) | 1 | For intermediate polishing |

| 012600 | Alumina polishing pad (20 pcs) | 1 | For final polishing |

| 012601 | Diamond polishing pad (20 pcs) | 1 | For intermediate polishing |

| 012610 | Coarse polishing Pad (20 pcs) | 1 | rough hewn |

| 012611 | Emery paper UF800 (20 pcs) | 1 | For PG and PFCE electrodes |

∗Do not use the polishing solution to the rough hewn polishing pad.

∗For polishing using emery paper, use only distilled water.

∗Polishing solution can not be used for the PG and PFCE electrodes.