RRDE-3A Rotating Ring Disk Electrode Apparatus Ver.3.0

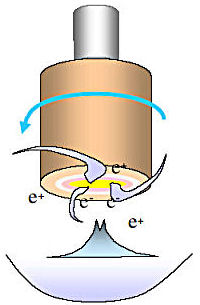

RRDE-3A is a miniature rotator system for use in constant rotation and hydrodynamic techniques by rotating ring disk electrode in electrochemistry field. A short stainless steel shaft and 12 mm diameter electrode provide a concentric circle electrode system that is capable of high accuracy.

RRDE-3A is electronically controlled by a proportional-integral closed loop circuit driven by a DC servomotor. The compact electrodes are easily and rapidly interchangeable. The unit also provides an adjustable valve system for inert gas purging inside the cell vial.

RRDE-3A can be operated as a stand-alone unit and directly controlled by Model 2325 or other instruments. During or between electrochemical analyses, a built-in gas control allows purging the sample.

Besides, easy to remove and replace the cell vial, easy for rinsing, cleaning, and replacing electrodes.

Troubleshooting

Technical Note

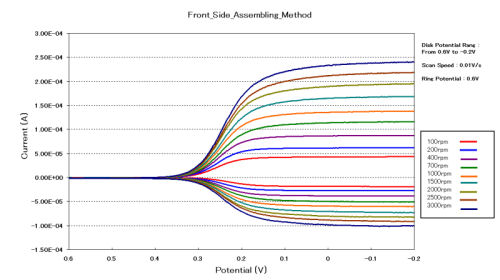

Hydrodynamic Voltammetry

Other potentiostats

Connections

RRDE-3A Ver.2.0

(Discontinued)

- Operating

- Features

- Specifications

- RRDE-3A content

- Working Electrode

- Movies

Features

- Compact design & easy operation

- Remote and manual controlled rotation

- Quasi-oxygen free sample vial design (up to 200 mL)

- Gas line connector is available

- Remote and manual controlled purge lines

- Teflon cap is adapted for ALS reference and counter electrodes

- Operable as RDE and RRDE

- Allows remote control from the PC (rotational speed ON/OFF and gas purge ON/OFF)

- Cell lead connects directly to Model 2325 or other potentiostats

- Open architecture for easy access to cell

Improvement points of Ver.3.0

RRDE-3A Ver.3.0 is electronically controlled by a proportional-integral closed loop circuit driven by a DC servomotor. The main frame structure has been improved and the weight of the instrument has been reduced from 6.0 Kg to 3.5 Kg.

Design changes

- The position of the power switch has been changed from the back to the front (next to the LCD display) (easy to operate).

- The color of the LCD display changed from green to blue.

- The clear warning button on the back has been removed. It is operated by the built-in software (easy to operate).

- The built-in power supply is changed to an external power supply (for easier maintenance of the instrument).

New maintenance mode for the software

The new maintenance mode has been added to the software to facilitate the operation of the instrument and to help customers to keep track of the rotational wear and tear of the instrument, and to regularly clean and maintain the mechanical system in order to keep the instrument in optimum working condition.

RRDE-3A Ver.3.0 can perform the following settings in the maintenance mode added by the software:

- Rotation speed setting unit change

- Display of total rotation time and time to next warning

- Clear warning display

- Remote control input voltage monitoring

Click on the links below for detailed information on the operation of the maintenance mode.

Specifications

| Size | 190 (w) x (Base: 230, Body: 120)(d) x 400 (h)mm |

| Weight | 3.5 kg |

| Rotational range | 100 to 8,000 rpm |

| Rotation stability | Error, < 1% at 100 to 1,000 rpm < 0.5% at > 1,001 rpm |

| Ring/Disk insulation resistance | > 10 M ohm |

| Electrode to lead pin contact resistance | 5 ohm |

| Rotator shaft | Stainless steel |

| Motor | 12 V, ironless core, low inertial DC servo |

| Power | 12 VDC |

| Operating temperature | 10 to 50 deg C |

| Relative humidity | ≦ 80% |

| Inlet gas pressure | 5 psi (34 KPa) maximum |

| Remote control | Motor ON/OFF TTL or relay input to back panel connection Purge TTL or relay input to back panel connection |

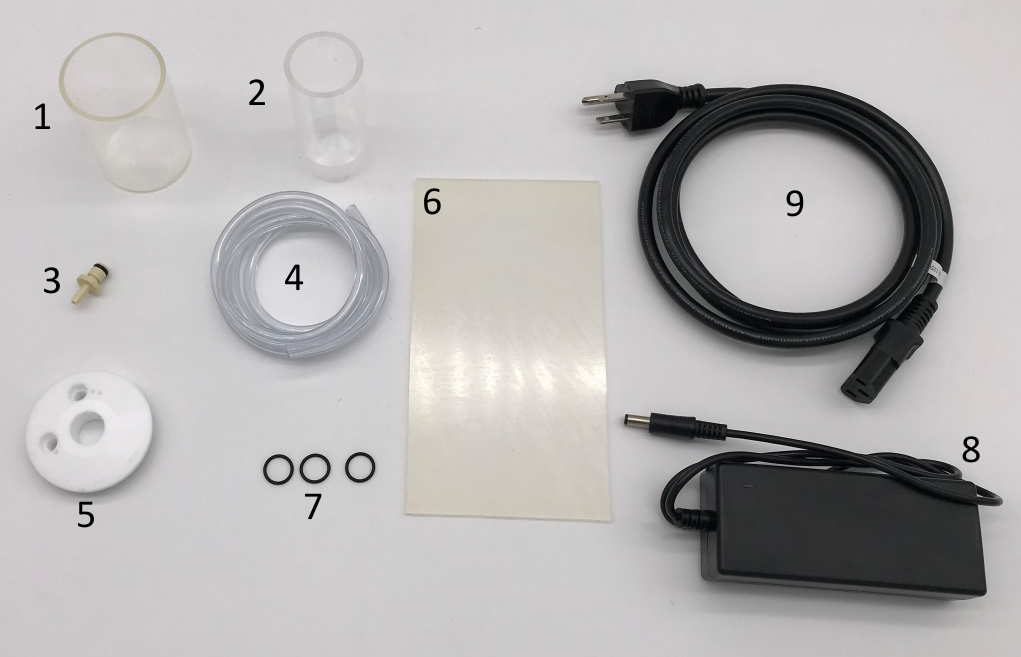

RRDE-3A Rotating Ring Disk Electrode Apparatus Ver.3.0 contents

RRDE-3A Rotating Ring Disk Electrode Apparatus Ver.3.0 contents. |

Cat# | Description | Qty | |

| 013725 | RRDE-3A Rotating Ring Disk Electrode Apparatus Ver.3.0 | 1 | ||

| Contents | Qty | |||

| 1 | (013580) | Sample vial for alkaline solution (100 mL) | 1 | |

| 2 | 012064 | Spin coating adaptor | 1 | |

| 3 | 012065 | Male connector for gas purge (PP) | 1 | |

| 4 | 013392 | TYGON tubing, OD1/4” x ID1/8” | 1 | |

| 5 | 013271 | RRDE-3A Teflon cap V.2 | 1 | |

| 6 | 012642 | RRDE-3A Sillicon sheet 100x180 mm | 1 | |

| 7 | 012975 | O-ring for RRDE-3A Bearing assembly | 3 | |

| 8 | - | AC adapter | 1 | |

| 9 | Power cable | 1 | ||

| - | Quick manual | 1 | ||

Optional items

The reference electrode and counter electrode are not included in the contents, they are sold separately.

Below a squeezed list of the optional items:

| Cat# | Description |

| 012167 | RE-1B Reference electrode (Ag/AgCl) |

| 012171 | RE-7 Non Aqueous reference electrode (Ag/Ag+) |

| 013373 | RHEK Reversible hydrogen electrode kit |

| 012961 | Platinum counter electrode 23 cm |

| 012962 | Gold counter electrode 23 cm |

| 012963 | Nickel counter electrode 23 cm |

| 014088 | Sample vial (100 mL) |

| 013580 | Sample vial for alkaline solution (100 mL) (10 pcs) |

| 013581 | Sample vial for alkaline solution (200 mL) (8 pcs) |

| 013582 | RRDE-3A Teflon cap (for 200 mL) |

| 013343 | O-ring for RRDE-3A Teflon cap V.2 |

| 013645 | O-ring for RRDE-3A Shaft (white) (3 pcs) |

| 012641 | O-ring for RRDE-3A Bearing assembly (10 pcs) |

| 012074 | CB-ES Remote cable |

| 009131 | Port plug |

| Option | |

For RRDE electrode Click here for detail |

Platinum ring disk working electrode |

| Platinum ring-glassy carbon disk working electrode | |

For RDE electrode Click here for detail |

Glassy carbon disk electrode |

| Platinum working disk electrode | |

| Gold working disk electrode | |

For DRE electrode Click here for detail |

DRE-PGK Pt ring/GC disk replaceable electrode |

| DRE-GCK disk replaceable electrode | |

| Electrodes of other materials and diameters will be fabricated on a custom basis. | |

※ RDE/RRDE/DRE electrodes are designed to be used in RRDE-3A Rotating Ring Disk Electrode Apparatus, we will not guarantee the operation when ALS RDE/RRDE/DRE electrodes are used in combination with RRDE apparatus made by other companies.

Movie contents

- RRDE-3A easy setup

- RRDE-3A disassembling/assembling for maintenance

- RRDE-3A motor rotation issue

- DRE electrode assembly methods Part1: Front Assembly

- DRE electrode assembly methods Part2: Rear Assembly