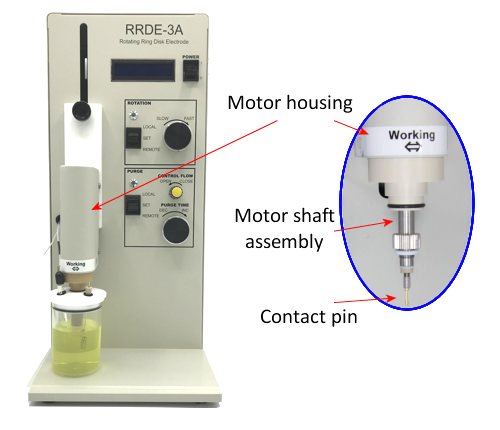

4. Motor and working electrode assemblies

After motor cable is removed from motor shaft assembly and motor connector, cell leads are released from counter and reference electrodes. Motor shaft assembly is turned counterclockwise, and then disassembled from the RRDE-3A. Since the top of the contact pin for RRDE-3A is very sharp, an appropriate rotating ring disk electrode (RRDE) should be carefully attached on the shaft assembly.

The working electrode is just screwed on the shaft. The contact is made with the contact pin attached in the shaft. As the contact pin is very sharp and fragile, handle it with care. To remove the working electrode, just unscrew it carefully.

When working electrode is assembled with motor shaft, an O-ring should be attached between the working electrode and the shaft to protect corrosion due to acidic or basic electrolyte.

Then the assembly needs to contact to the ground. All lines are Active Low.

The following operational instructions are given under "Initial instrument operation" (Chapter 5) to remote rotation.

Gas purge:

The LED is flashing when the purge function is ON, either remotely or manually.

To control purge remotely, the purge and rotating remote cable are connected on the back panel of the RRDE-3A. Time of the purging is controlled manually or via TTL control by the potentiostats software.

Do not use Hydrogen gas as purge, because teflon tubing is used for gas flow, and small molecule such as hydrogen is penetrated from the teflon tubing. Hydrogen gas has possibility to leak from the teflon tubing. Please use inert gas such as Nitrogen or Helium gas as purge purpose.

Before set the sample vial, check the Teflon cap holes. If the purging gas outlet hole is blocked, the increase of the sample vial internal pressure could happen, causing reverse flow and leakage of the sample.

General instructions:

Switch power OFF on the back panel. Connect the power cable. The main power connection must have proper grounding.

WARNING: Any disconnection of the ground wire either inside or outside the instrument may be dangerous. DO NOT DISCONNECT the ground.

Check that the top of the electrode body is connected on the shaft firmly. Then switch power ON.

Set the rotation speed at 1,000 RPM and start rotation. Please do not touch the RRDE shaft when it is rotating. Visually inspect the shaft and electrode body during rotation. It should be straight.

Stop rotation by switching the rotation button.

The solution should be thoroughly purged with the gas purging function on the front panel of the unit, before use. The most effective purging is done by using a low pressure inert gas source connected to the gas tubing on the rear panel for 15min. The "gas adjust valve" controls the rate of purging.

Fig.4-2 Assembly names of RRDE-3A front panel

2. Power On/Off Switch

3. rpm LED: The LED is ON when rotation is turned ON,

either remotely or manually

4. Rotation control switch (Set, Local, Remote)

5. Rotation speed knob (X10)

6. Purge LED: The LED is ON when purge is turned ON,

either remotely or manually

7. Gas purge switch (Set, Local, Remote)

8. Gas purge flow control knob

9. Purge time knob

10. Motor shaft assembly

11. Reference electrode

12. Counter electrode

13. Teflon tube for gas purge

14. Teflon cap

15. Working electrode

16. Sample vial for alkaline solution

17. Silicon sheet