2. Instrument setup

Inspection of shipment:

After unpacking the instrument carefully, we recommend to check the package contents and inspect for breakage. In the table lists the package contents of the RRDE-3A. This list is subject to change the parts. It is strongly recommended to refer to the packing slip with your instrument. Assemblies of these various parts will be outlined in the following chapters. The shipping box and packing materials retain until you have fully tested the unit to be certain that no damage was incurred during shipping. If a shortage exists, you should contact with local distributor or ALS Customer Service and describe the shortage. A replacement part will be sent immediately subject to stock availability.

| Catalog No. | Description | Quantity |

| 013606 | RRDE-3A Rotating Ring Disk Electrode Apparatus Ver.2.0 | 1 |

| (013580) | Sample vial for alkaline solution (100mL) | 1 |

| 012064 | Spin coating adapter | 1 |

| 012065 | Male connector for gas purge (PP) | 1 |

| 013392 | TYGON tubing, OD1/4 x ID1/8 | 1 |

| 013271 | RRDE-3A Teflon cap V.2 | 1 |

| 012642 | RRDE-3A Silicon sheet 100x180mm | 1 |

| 012975 | O-ring for RRDE-3A Bearing assembly | 3 |

| Instruction manual | 1 | |

| Power cable | 1 |

Instrument setting:

- Provide a surge-free power source. Other laboratory equipment such as ovens, vortex mixers, centrifuges, and large motors may cause spikes in the power supply.

- Make sure that all components of the system share the same ground circuit. It is the best way to accomplish by plugging all the components into a multi-outlet power strip. Plugging the components into independent

outlets can produce ground loops, which occur baseline noise.

- Place the RRDE-3A on a stable bench free of vibrations.

- Select a room where temperature remains stable throughout the day. Avoid installing the RRDE-3A near window air ducts, ovens, and refrigerators. A water-jacketed cell may be required for very precise work.

- Place the RRDE-3A away from any busy and congested areas. Remote and isolated areas are the best for high-sensitivity work.

- Avoid very dry and carpeted areas. Static electricity affects instrument performance. Antistatic floormats and benchmats are useful if spiking caused by static charge is a problem.

- Avoid areas where radio-frequency interference occurs. Beeper-type pager causes a problem.

Warning:

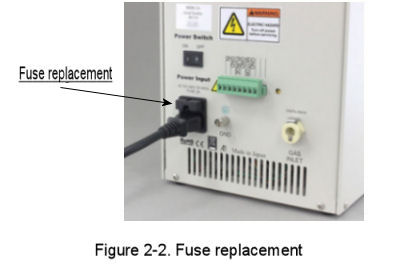

When RRDE-3A power is ON, do not touch motor shaft and stop it. RRDE-3A is stopped due to its safety. If it does not work, inside fuse in the circuit board is blown out.

Power requirements:

The RRDE-3A can be used in the power supply range 100 - 240 V (50/60 Hz). Connect the provided AC adapter and power cable to the unit.

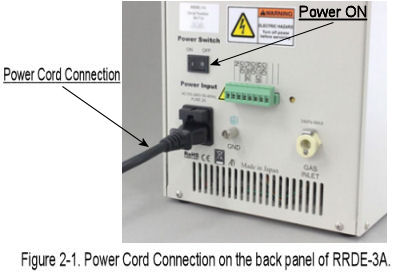

Power cord connection:

Put the power cord into the port located in the back-panel (Fig. 2-1). Then, power switch ON (position “I”) or power switch OFF (position “O”).

Fig. 2-1. RRDE-3A Power cord connection.

The electrode leads are connected to the potentiostat on the end of the cell lead cable into the Electrodes female connector on the rear panel of the potentiostat.

Back panel controls and connections :

Fig. 2-2 RRDE-3A back panel.

Three cables are required to connect the RRDE-3A to the potentiostat. Electrode rotation can be automatically turned ON or OFF by TTL control. The control line is a cable between the remote terminal on the back of the RRDE-3A and the GND and RDE on the back of the potentiostat (See Fig. 3-1).

In order to control purging remotely, the purge cable should be connected to remote terminal on the back of the RRDE-3A (Fig. 2-3; Fig. 3-1).

Since the cable controls the electrode rotation, the other end of this cable should be connected to the remote port on the back of the potentiostat (See Fig. 3-1).