7. Maintenance

- 7.1 General maintenance

- 7.2 Maintenance mode

- 7.3 Exchange of working electrode

- 7.4 Electrode polishment

The RRDE-3A is a very rugged instrument and, with proper care, should give years of service.

The following is a brief list of cautions and general maintenance

considerations that will extend the lifetime of the instrument. When turn on the power, do not touch RRDE-3A shaft assembly.

- Follow customary, good laboratory practices

- Clean all spills, especially salt solutions, on or near the cabinet immediately

- Avoid placing the unit in a corrosive atmosphere

- Avoid dropping, shaking, or other forms of mechanical abuse to

prevent loosening any of the components or subassemblies

- Clean gas lines (rinse and wipe dry) after use

- Do not bend the counter electrode when removing or placing the cell vial. Repeated bending might cause break to the wire

RRDE-3A Ver.3.0 adds the function of the instrument maintenance mode. The following settings can be made in this mode:

- Change of speed setting unit

- Display of total rotation time and time to next warning

- Clear warning display

- Remote input voltage monitoring

The following describes how to enter to the instrument maintenance mode and perform various settings.

How to enter in the maintenance mode

Fig. 7-2-1 Initial display.

SET → LOCAL → SET → LOCAL → SET → REMOTE → SET

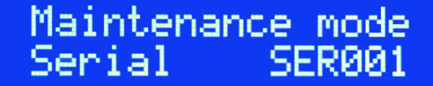

Fig. 7-2-2 Maintenance mode

When you finish the maintenance mode, turn off the power and then turn on again.

Maintenance mode menu

The switch the menu can be by turning the rotation speed setting knob.

The maintenance mode menu is as follows.

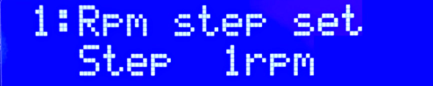

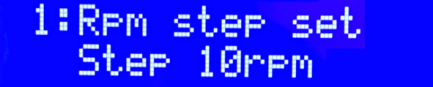

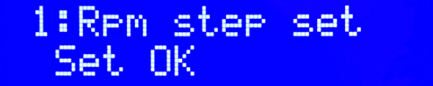

Fig. 7-2-3 1:Rpm step set

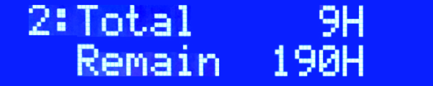

Fig. 7-2-4 2:Total time

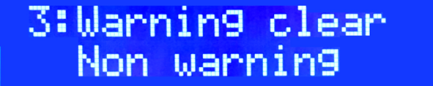

Fig. 7-2-5 3:Warning clear

Fig. 7-2-6 4:Remote monitor

1. Change the rotation speed setting unit

It is possible to change the setting unit of the rotation speed.

Set the menu to 1:Rpm step set and set the rotation control switch to LOCAL to shift to the mode.

The rotation speed knob switches the setting unit between 1 rpm and 10 rpm.

Fig. 7-2-7 Step 1 rpm

Fig. 7-2-8 Step 10 rpm

Fig. 7-2-9 Set OK

2. Total rotation time & next warning time display

Fig. 7-2-10 2:Total rotation time and remain time for next warning

3. Clear warning display

Fig.7-2-11 3:Warning clear

Use the rotation speed setting knob to switch between Yes / No. If you return the rotation control switch to SET with Yes displayed, the brush cleaning and brush replacement warning display will be cleared.

4. Remote voltage confirmation display

Fig. 7-2-12 4:Remote monitor

By connecting the remote terminal on the back panel of the RRDE-3A to the potentiostat, the actual voltage input from the potentiostat can be checked.

Fig. 7-2-13 Remote monitor

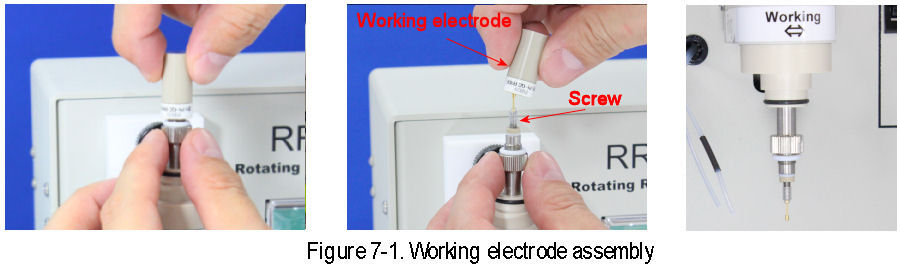

Exchanging of working electrode: The electrode body to the protruding shaft should be attached by threading it on lightly, while holding the electrode shaft steady with the shaft screw.

DO NOT BEND and DO NOT OVER TIGHTEN!

You should feel the contact pin compress against the electrode and turn the electrode until it lightly rests against the rubber O-ring.

If the electrode is overtightened, it will align with the very end of the threaded portion of the shaft and will be eccentric. By threading the electrode against the O-ring, the ground diameter of the shaft will align the electrode and allow for a more consistent position. To remove the effect, those operations should be revered.

- Remove the electrode carefully as outlined above.

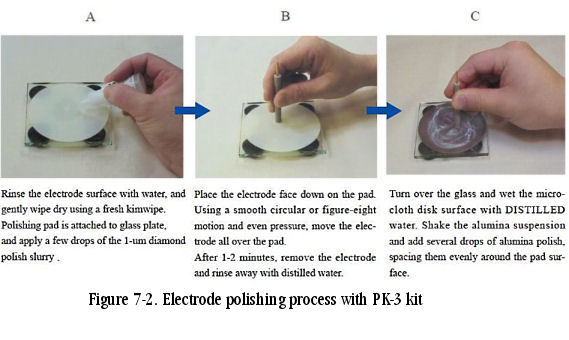

- According to the instructions using PK-3 Polishing Kit, the electrode should be polished. The objective of the polishment is to remove the redox reaction products and/or physical adsorption accumulating during some experiments.

The rate of electrode coating (and corresponding decrease in response) will depend upon the following factors:

- Analyte molecule

- Concentration of analyte molecule

- Composition of stationary phase

- Applied potential

- Frequency of use

- Analyte molecule

The electrode needs repolishing after each experiment though depending on the application. On the other hand, Rotating ring disk electrode (RRDE) and hydrodynamic modulation applications have the advantage of a moving solution which helps to remove redox products, and often deals with lower concentrations of analyte than those in voltammetry methods with non-stirred solutions. The requirement of repolishing greatly varies in the application. Polishing is justified when a gradual decrease in electrode response is observed. Electrodes can also accumulate contaminants by adsorption from the environment such as cigarette smoke, aerosols, and other airborne materials.

The polishing process might be able to remove a very small amount of electrochemically active materials.

To refresh the electrode, three different polish systems are used, progressing from coarse particle sizes to very fine polishing powders. Many electrodes surfaces only use a single polishing step to physically remove the contaminants. Besides, rare metalic electrodes (gold, silver, and platinum) may perform best with either an alumina or a diamond polishing. To determine whether the desired results are obtained, it is the best way to start with the diamond polishing. Then, chemically modified (gold/mercury amalgam) and glassy carbon electrodes tend to require two to three steps of abrasives in order to restore the original mirror.

All polishing steps require extensive rinsing of the electrode before moving onto the next stage. Without extensive rinsing, the contaminated materials from the previous polishing step will interfere the progression towards a finely polished surface. Under the polishing, you take care not to corrode the softer electrode materials below the level of the supporting plastic. To avoid the corrosion, always polish the electrode on a very flat surface.

On the basis of handling the working electrode, always follow the general precautions listed below:

- It is important that you use only ALS polishing materials and follow the recommended procedure. The PK-3 kit provides the materials needed for all polishing procedures.

- Polish the electrode on pads attached to glass plate provided in PK-3 kit. Under polishing, you must keep the electrode surface as parallel to the surface of the glass as possible . This is especially important for the RRDE and RDE working electrodes and will ensure that the surrounding plastic is not worn unevenly. You must be careful to polish very slowly to maintain the surface as flat as possible. Any deviation will be obvious when the electrode rotates.

- Do not attempt to remove the softer electrode material from the supporting plastic. These treatments will not recover the electrode.

- When drying the electrodes, you dry them at room temperature.

Heating will cause problems due to the difference in the coefficients of expansion of the electrode material and the supporting plastic. - It must be handled very carefully to ensure that no debris could enter the open back of the electrode body. The opening must be kept clean in order to effectively contact the electrode material to the spring loaded pin.